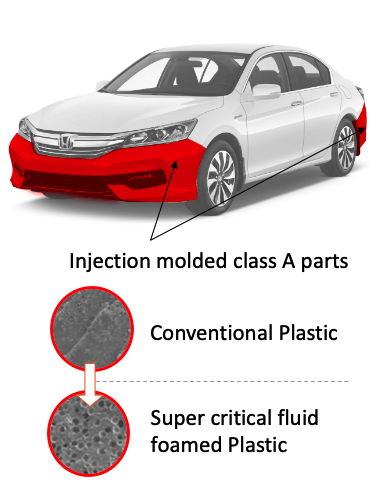

Foamed thermoplastics for automotive lightweighting in Body-In-White applications

USING SUPERCRITICAL FOAM INJECTION molding technologies to lightweight hang on parts such as bumpers and trims. This is part of a four-year project that to address the needs of Automotive Original Equipment Manufacturers (OEM).

NUCLEATING

Principal investigator Dr. Srikanth Pilla, Bosch and Jenkins Endowed Professor, “Within the technology portfolio for lightweighting, much of the ‘low-hanging fruit’ has been implemented already — for example, engine downsizing. We believe there’s potential for efficiency gains in the area of load-bearing, structural closure systems at a reasonable price point.”

PARTNERSHIPS AND ACHIEVEMENTS

PROJECT GOALS

- Achieve a 15% Lightweighting

- No compromise surface quality

- Paint compatibility and adhesion similar to baseline

- No surface defects at extreme temperatures and humidity

- Must meet all mechanical requirements of the baseline parts

- Very minimal additional cost

PARTNERS

- Honda R&D Americas