Enabling Industry 4.0 for Multi-tiered Quality and Process Control in Precision Manufacturing of Composites

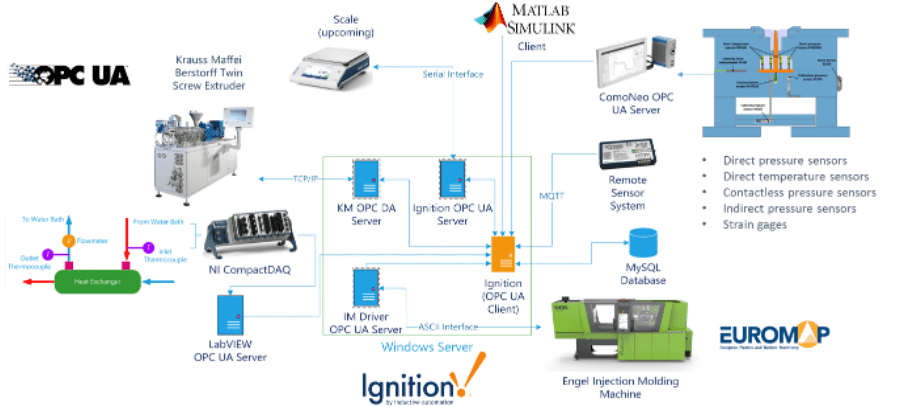

AS PART OF A SCRA GRANT for the unification of various connected systems, Clemson researchers deployed a supervisory control and data acquisition (SCADA) system program called Ignition on a Windows server hosted at a Clemson University data center. The system was connected to a MySQL database for continuous logging of all desired parameters for the various devices and machines connected to Ignition.

DATA ACQUISITION

The program enables connections via OPC UA, MQTT, Modbus TCP, and various proprietary drivers (e.g. Siemens, Omron). A wide range of devices were connected to Ignition, including the injection molding machine (through a route ending in an OPC UA server), an in-mold sensor system, a twin screw extruder, a remote data acquisition system for downstream extrusion equipment, and multiple remote temperature and input sensors throughout the labs. Interfaces were made to visualize the data from these systems on both desktop and mobile devices and enable control where available.

PARTNERSHIPS AND ACHIEVEMENTS

PROJECT GOALS

- Develop methods to predict part quality of an injection molded part using process parameters and data from the machine.

- Develop database and machine learning systems designed to work with injection molding processes.

- Develop unique tool with sensor to measure temperatures and pressure inside the cavity.

- Develop more robust feedback loop to optimize process parameters.

PARTNERS

- South Carolina Research Authority (SCRA)

PUBLICATIONS